TURNED AND MILLLED PARTS

TURNED AND MILLLED PARTS

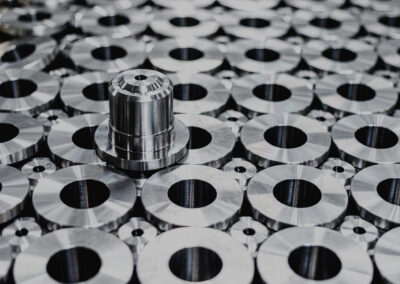

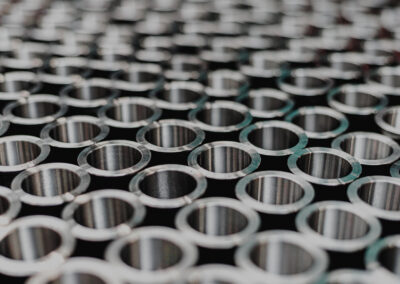

Our company uses only state-of-the-art CNC lathes to produce high-quality parts. These lathes have 3 to 12 steered axes, depending on the model, allowing high-precision machining of highly sophisticated components. And with the use of fibre-guided magazines, they can produce up to Ø65 mm from 3 m fibre.

With our modern and flexible machine fleet, we can perform simple and complex turning and milling tasks of high quality. Few companies compete with the size and flexibility of our technical capabilities – even globally.

Our products are manufactured primarily for the benefit of internationally renowned automotive, commercial vehicle, railroad and mechanical engineering customers, who are world leaders in the automotive and mechanical engineering industries. At the same time, we also cater to smaller companies which value high quality and cost-effective production.

Beyond the automotive industry, we supply our customers in the pneumatic, medical, and other fields with components that meet the highest technical demands.

The production runs in 3 shifts and continuous shifts to maximize efficiency.