MEASURING DEVICES

Focusing on quality

MEASURING DEVICES

One of MATRO’s competitive advantages is its high quality, which is also marked by the recognition of many customers and the title awarded by Denso as the “European Supplier of the Year 2016” or just recently the “Top Performance Award 2019”.

The Japanese partner awards this based on quality indicators, delivery accuracy, successful implementation of projects, increase in turnover and competitive price, i.e. objective parameters. All of this demonstrates MATRO’s commitment to quality.

The key to quality is double; employees’ responsibility, commitment and high standards complemented by a quality-oriented benefit system. On the other hand, the use of modern manufacturing technology and measuring methods ensures the production of high-quality products.

We work together with our partners to provide the best quality, paying attention to their feedback and suggestions. Therefore, we use multiple controls in our manufacturing processes to achieve the highest quality.

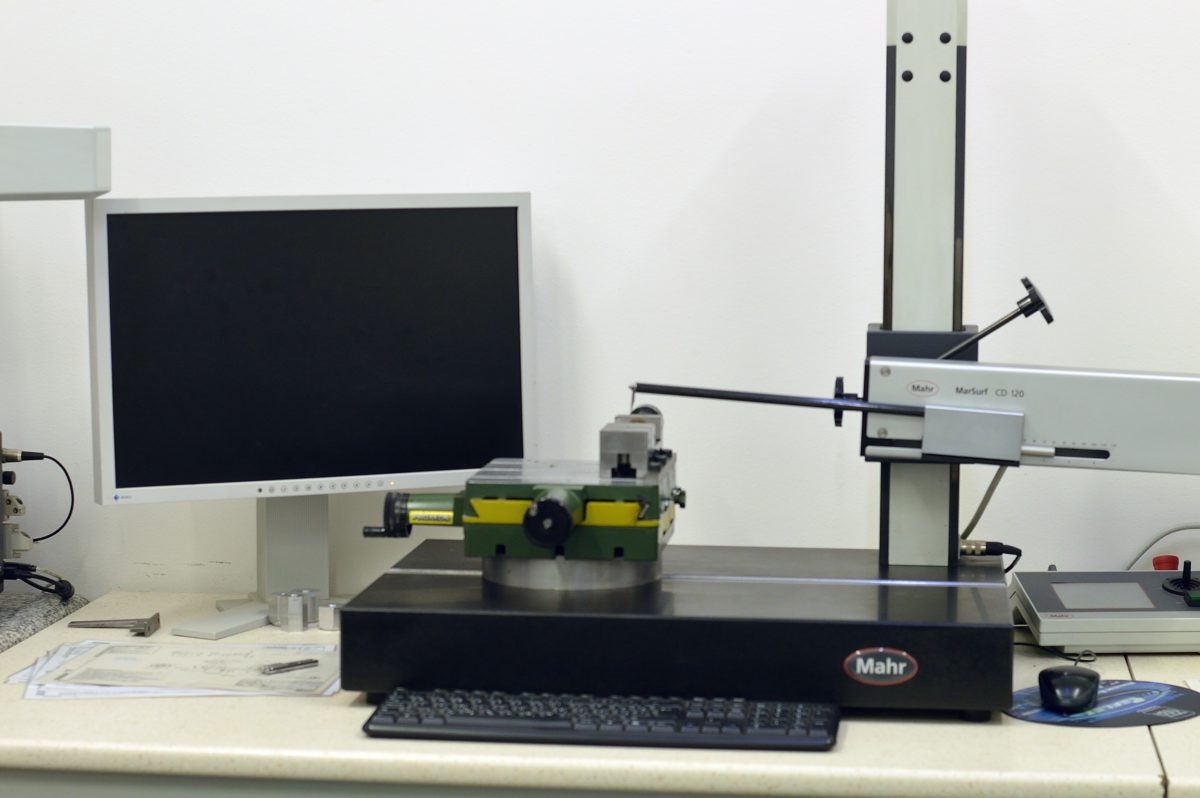

In addition to the commonly used measuring and control instruments, we use many other measuring tools to control the manufacturing process – contour measuring machine, circular and roughness meter, 3D coordinate measuring machine.

Our measuring instruments are subject to planned controls, either in-house or at an external accredited laboratory. In fact, some of our measuring instruments are calibrated by our partners for perfect results in order to avoid discrepancies between measuring instruments. This also eliminates the possibility of errors due to measurement differences.