PRODUCTS

4 MAIN AREAS

PRODUCTS

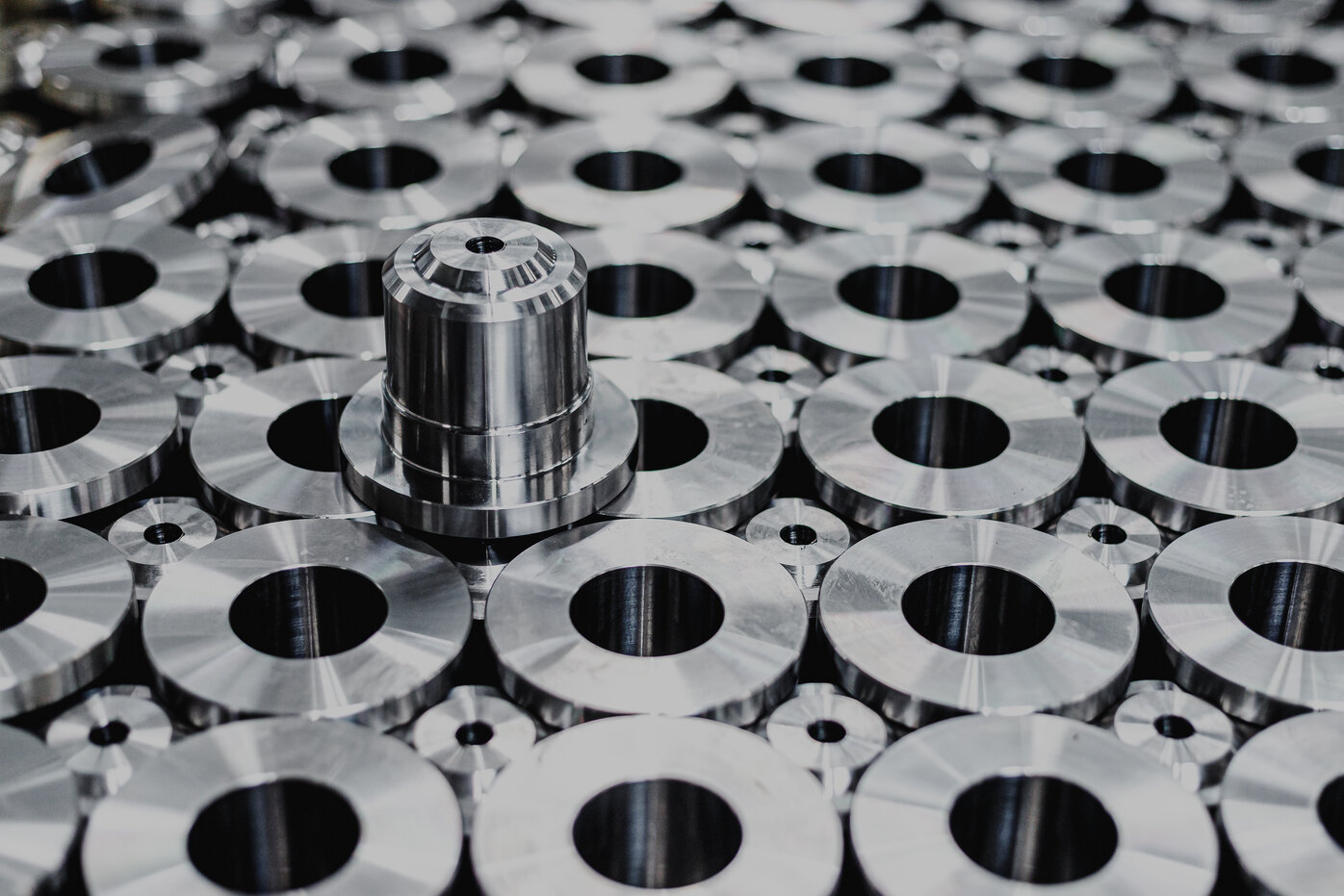

At MATRO, we only use state-of-the-art CNC lathes to produce high-quality parts. These lathes have 3 to 12 controlled axes, depending on the model, allowing high-precision machining of high-complexity parts. Fibre-guiding magazines are also suitable for manufacturing up to Ø65 mm from 3 m fibre.

With our modern and flexible machine fleet, we can perform simple and complex turning and milling tasks of high quality. Due to the size and flexibility of our technical capabilities, few companies compete globally.

Our products are manufactured primarily for the order of our internationally renowned automotive, commercial vehicle, railroad and mechanical engineering customers, who are world leaders in the automotive and mechanical engineering industries. At the same time, we also cater to smaller companies which value high quality and cost-effective production.

In addition to the automotive industry, we supply our customers in the pneumatic, medical and other fields with components that meet the highest technical demands.

The production runs in 3 shifts and continuous shifts to maximize efficiency.

PRODUCTION

CHARACTERISTICS

Wide range of production quantities

We are one of the few companies that can produce small and large series of enormous quantities of machined and milled parts at the same time. Also, we can create a minimal number of complex products (as low as 1-2 piece per year) cost-effectively.

Contributing to planning

The more complex a product is, the more critical it is to optimize production. Optimization applies to both the production process and the amount of material used. As a result of the combined work of our design engineers and production managers, we can optimize the manufacturing processes of complex components, which bring benefits both in terms of production time and cost.

High-quality

Quality is measurable and is measured by our international partners. MATRO is recognized year after year for its high-quality work. Most recently, DENSO chose us as the “REGIONAL SUPPLIER OF THE YEAR” based on objective metrics, awarded to Europe’s best supplier partner. Just recently we have received the “BEST TOTAL PERFORMANCE” award from DENSO as well.

Flexibility

Deadlines also change regularly and sometimes dynamically in the automotive industry. Adapting to this requires flexibility from an outstanding supplier partner. At MATRO, we strive to meet the occasionally fast-changing demands of our partners, as far as possible.

Swift pace

We are proud to be able to launch a product – even a brand new one – at a swift pace. We have the technical and human needs to do this. This type of speed is one of our critical competitive advantages.

EXPERTISE AND EXPERIENCE

QUALITY PRODUCTS

There are several unique factors behind the quality that MATRO provides, all of which we pride ourselves on.

In addition to the tremendous experieresult in the excellencence accumulated over decades, the day-to-day continuous innovation steps together are the engine of development. This is coupled with a dedicated and highly skilled team of employees who are committed to our commitment to quality.

This is how we can continually enter new markets with new products. Currently, we want to focus primarily on the automotive industry, but in the coming years, we aim to focus on other areas, including health.